Water Tretment Solution Process |

|

|

Membrane System... |

|

|

|

|

Reverse Osmosis System |

|

Ultra Filteration System |

|

Micro Filteration System |

|

| |

Area Of Industries |

|

|

|

Pharmaceutical Industries |

|

Food & Beverages Industries |

|

Dairy Industries |

|

Paper And Pulp Industries |

|

Chemical Industries |

|

Textile Industries |

|

Metal & Tanneries Industries |

|

Water Tretment Industries |

|

West Water Tretment Industries |

|

|

| |

| |

|

| |

|

|

|

| |

Complete Automatic Rising, Filling and Capping machinery |

|

|

| |

Automatic 20 Jar Rinsing Filling And Capping Machine. |

| |

Capacity :- 240 Jar Hes Hours

4 Bottles Per Minute

(pc/pet-5gallon 6gallon bottles) |

|

| |

Automatic Liquid (Pouch) |

| |

|

APPLICATION:

Suitable for packing of Milk, Water, Soyabean Milk, Fruit Juice, Beverage, Ice Drink, Soya Sauce, Vinegar and Wine etc. In Pouches

|

| |

| TECHNICAL SPECIFICATIONS: |

| |

| Output |

:- |

1800-2000 bags/hour,per hours. |

| Capacity |

:- |

200ml-500ml can be adjust. |

| Power |

:- |

220v/380v 1.6 kw. |

| Width |

:- |

320mm/240mm approx. |

| Weight |

:- |

400 kgs approx. |

| Size |

:- |

970x870x1970mm approx. |

|

|

|

| |

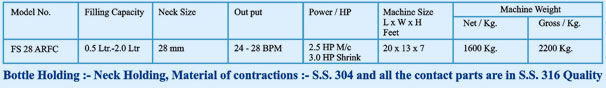

Fully Automatic Rinsing Filling and Capping Machine FS 28 ARCF |

| |

|

|

| |

Automatic Liquid Filling Machine For Bottles. |

| |

|

| |

Semi Auto Outer Brushing, internal Rinsing Filling And Capping Machine. |

| |

|

| |

| |

| |

Automatic Cup/Glass, Rinsing Filling & Sealing Machine |

| |

| Outer Brushing |

:- |

All Side with Soap and Raw Water |

| Internal Rinsing |

:- |

Raw Wate, Chloring water and Final Water |

| Material of contractions |

:- |

S.S.304 And all the contact parts is in S.S. 316 Quality |

| |

|

|

|

| |

|

|

| |

| TECHNICAL SPECIFICATIONS :- |

| |

| Source |

:- |

220V, 50Hz 2.5 KW |

| Output |

:- |

1000-1800 CUP/HR |

| Tempt |

:- |

0-300 C |

| Seal Material |

:- |

Pe, Pp, Pet/Pe/Al |

| Dimension |

:- |

1700 x 540 x 1400 mm |

| Approx Weight |

:- |

300 Kg Approx |

|

| |

| |

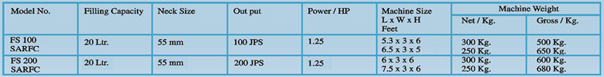

Automatic Rinising Filling and Capping (500 ML to 2 LTR pad Bottling Machine) |

| |

|

| |

Bottle Filling 10x25 |

| |

|

| |

Shrink Tunnel |

| |

|

| |

These compact and user-friendly shrink tunnels are used to pack products using PVC/POF/LDPE shrink films. The basic features of the tunnels are variable speed drive to control the speed of the conveyor, High velocity air cutter blowers for Uniform Airflow System, faster heating system, and variable temperature control. Some of the other optional features, which are available, are silicon sleeves for the conveyor rods, fully stainless steel construction, variable speed drive for the blower, in feed and out-feed extension conveyors, Mesh type conveyor, Roller type, Teflon belt conveyor, etc., A speed of 2-4 packs / Minute |

| |

Paper Sticker Labeler |

| |

|

| |

These model machines are custom made system for Labeling of Round, Square or Triangular Bottles. The paper sticker labeler applies the Label Precisely on the bottle without deforming the bottles. Special censor circuit is engineered to cut the label precisely. The system can be offered between 40 Labels per minute up to 200 Labels per minute. Various bottle sizes can be used by implementing change parts. [Change parts for various sizes are optional] |

| |

Cup & Glass Machine |

| |

|

| |

Bottel Machine |

| |

|

| |

Pet Blow Moulding Unit 30x12 |

| |

|

| |

| |

|

|